Like with every business, if you are to stay in business you have to move with technology. When I first started in the custom rifle stock and pistol grip business, I started by making patterns and then tracing them on a manual duplicator. When I opened my Turner Customs business full time in 1990, I opened with a manual duplicator and a very large foot print CNC machine that was designed for doing flat work.

I eventually owned and sold 6 different manual duplicator machines and finally made the decision to go all CNC. CNC is an acronym which stands for Computerized Numerical Control and basically like any computer program, it all boils down to numbers! I also use CAD and CAM software to finish out the process. CAD stands for Computer Assisted Design and CAM stands for Computer Assisted Manufacturing, or Machining. I have heard and read it both ways.

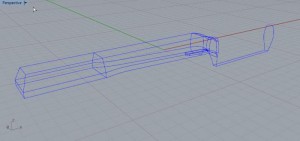

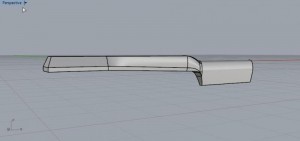

For my system, I use Rhino 3d V5 for my CAD and for my 3d modeling program. For my CAM software, I use a program that sits inside Rhino called MadCam, which is another acronym which stands for Mold and Die Cam. This particular piece of software is called a plugin by Rhino as it is not a standalone software, but has to reside inside Rhino to function.

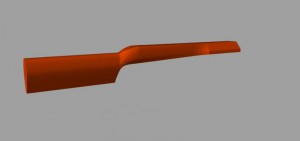

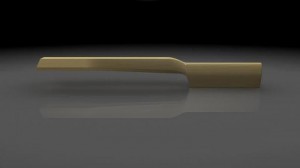

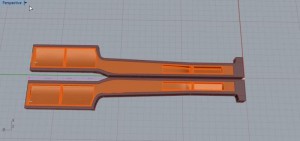

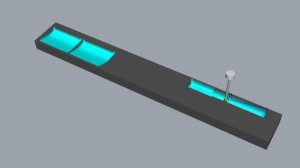

The following photographs show the process for a chambered benchrest stock done for a customer who needed the lightest possible stock so I made the stock in two halves, hollowed each half with the CNC, then glued the two halves together to form the blank from which the final stock shape was carved. From start to finish below: